The DTF Heat Transfers process uses a heat press to apply intricate designs directly onto fabric, eliminating screens and plates. It starts with high-resolution digital art files printed on transfer paper, then transferred to fabric via heat. For efficient bulk production, organize a well-structured design library in suitable formats and optimize settings for your printer. Streamline workflows by automating tasks, reducing errors, and integrating software with your DTF printer for enhanced productivity and quality control.

Preparing for bulk DTF (Direct-to-Fabric) heat transfer orders requires a strategic approach to ensure seamless execution. This article guides you through optimizing your process, from grasping the fundamentals of DTF Heat Transfers to streamlining production workflows. First, understand the DTF process and its unique advantages. Next, stock and organize design resources efficiently. Lastly, focus on workflow optimization for faster turnaround times. By following these steps, you’ll be well-prepared to handle large-scale DTF orders effectively.

- Understand DTF Heat Transfers Process

- Stock and Organize Design Resources

- Optimize Production Workflow for Efficiency

Understand DTF Heat Transfers Process

The DTF (Direct-to-Fabric) Heat Transfer process is a cutting-edge technology revolutionizing custom apparel creation. It involves applying intricate designs directly onto fabric using a heat press, enabling the production of custom t shirts and other garments with exceptional detail and quality. This method streamlines the design-to-product journey, making it ideal for bulk orders. By eliminating the need for screens or plates, DTF printing for light fabrics offers unmatched speed and versatility.

Understanding the DTF Heat Transfers process is crucial for efficiently preparing bulk orders. It begins with creating or sourcing high-resolution digital art files, ensuring they meet specific format and size requirements. These designs are then printed onto transfer paper using an inkjet printer. The transfer paper acts as a carrier, allowing for precise application of the design to various fabric types during the heat press operation. This method’s precision and efficiency make it perfect for creating custom heat press applications on a large scale.

Stock and Organize Design Resources

When preparing for bulk DTF heat transfers orders, having well-organized design resources is paramount. Begin by compiling a library of high-quality designs that are ready to be printed. This can include graphics, text, and images sourced from various providers or created in-house. Ensure these assets are saved in the correct formats (like SVG, PNG, or JPEG) and optimized for DTF printing to avoid any issues during the transfer process.

Organize your design resources into categories based on product types, such as t-shirts, hoodies, or mugs. Use folders or cloud storage solutions to maintain a structured layout, making it easy to access and retrieve designs when needed. Additionally, familiarize yourself with the capabilities of your DTF printer. Different printers have varying specifications for file size, resolution, and color depth, so adjust your design settings accordingly. This preparation step ensures smooth production workflows and high-quality bulk DTF shirt production using direct to film personalized hoodies.

Optimize Production Workflow for Efficiency

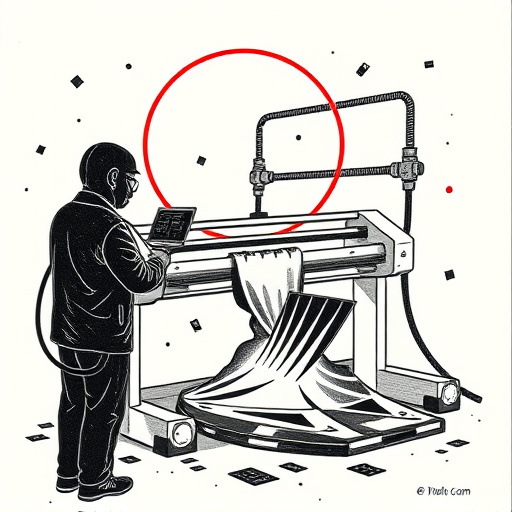

To prepare for bulk DTF heat transfers orders, optimizing your production workflow is key. Efficiently managing your DTF printer and materials ensures a seamless process from design to delivery. Streamline your operations by organizing tasks in a logical sequence; this could involve setting up dedicated stations for design, cutting, printing, and packaging. Utilizing software that integrates with your DTF printer can automate many steps, reducing human error and increasing speed.

Remember that a well-oiled workflow not only enhances productivity but also improves the quality of your DTF for Apparel products. With clear processes in place, you can handle larger orders without compromising on precision or speed. This approach ensures that every step, from understanding the design requirements to applying the heat transfer, is executed with expertise and consistency, ultimately satisfying customer demands for high-quality DTF meaning products.

Preparing for bulk DTF Heat Transfer orders requires a strategic approach. By understanding the DTF process, organizing design resources efficiently, and optimizing production workflows, businesses can ensure seamless order fulfillment. These steps are crucial in meeting demand promptly and accurately, making your operation a true game-changer in the print-on-demand industry.