DTF (Direct to Fabric) Heat Transfers have transformed printing by allowing intricate, vibrant designs on diverse fabrics through heat-activated ink. To achieve optimal results in bulk production, prepare files in high-resolution EPS or PNG formats (300 DPI or higher), ensure precise color and adequate contrast, and use top-quality DTF printers with correct settings. Vector graphics like SVG or EPS are ideal for clean lines and crisp details, while adhering to guidelines like avoiding tiny details and adding a transparent border optimizes print quality using DTF transfer sheets.

“Unleash your creativity with DTF (Direct to Fabric) heat transfers! This innovative printing method demands precise artwork preparation to achieve stunning results. In this guide, we’ll walk you through the process of optimizing your designs for DTF heat applications. From understanding the unique requirements to final file checks, learn how to prepare artwork that will transform your fabric creations. Get ready to dive into the world of DTF Heat Transfers and elevate your printing game.”

- Understanding DTF Heat Transfers and Their Requirements

- Pre-preparation: Optimizing Your Artwork for Transfer

- Final Touches: File Format, Resolution, and Printing Guidelines

Understanding DTF Heat Transfers and Their Requirements

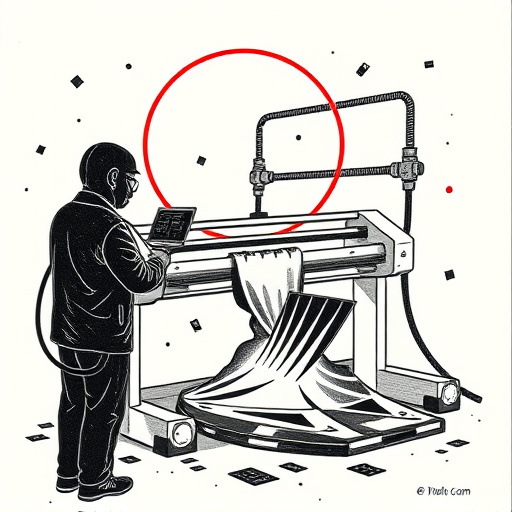

DTF (Direct to Fabric) Heat Transfers have gained immense popularity due to their ability to produce vibrant and detailed designs on a variety of fabrics. This innovative printing method involves transferring heat-activated ink directly onto fabric, resulting in high-quality, durable prints. Understanding DTF Heat Transfers requires recognizing that they cater to diverse applications, from personalizing apparel to mass production. In the context of bulk DTF shirt production, for instance, precise file preparation is crucial to ensure optimal print quality and consistency.

The requirements for DTF Heat Transfers are specific to maintain the integrity of the final product. File formats such as EPS (Encapsulated PostScript) or PNG (Portable Network Graphics) are typically supported by DTF printers, with a focus on high resolution and precise color representation. Moreover, ensuring that designs have adequate contrast and do not contain tiny details or text smaller than 1-2mm is essential for successful printing. Selecting the right printer, like one of the best DTF printers available, can greatly enhance production efficiency and print quality, making it a key consideration in the process.

Pre-preparation: Optimizing Your Artwork for Transfer

Before preparing your artwork files for DTF (Direct-to-Fabric) heat transfers, it’s crucial to optimize your designs for the best results. Since DTF heat transfers involve applying intricate patterns and detailed images directly onto fabric, ensuring your artwork meets specific requirements is essential. Start by using high-resolution images, typically 300 DPI or higher, as this ensures sharp details when printed. Vector graphics are particularly ideal for their scalability without losing quality, making them perfect for custom DTF transfers.

Additionally, consider the color mode; CMYK is the standard for printing, especially for DTF heat transfer paper. Converting your artwork to CMYK will ensure accurate representation on the final product. Keep in mind that the background should be solid and simple, as any intricate patterns or gradients might affect the heat-transfer process. Using a best DTF printer with high precision settings will further enhance the quality of your custom DTF transfers.

Final Touches: File Format, Resolution, and Printing Guidelines

When preparing artwork files for DTF (Direct-to-Fabric) heat transfers, paying attention to the final touches—file format, resolution, and printing guidelines—is paramount. For seamless integration with DTF printers, it’s crucial to save your designs in vector formats like SVG or EPS. Vector graphics ensure clean lines and crisp details, which are essential for high-quality DTF printing. Resolutions should ideally be 300 DPI (dots per inch) or higher to maintain image clarity when scaled up during the transfer process.

Adhering to specific printing guidelines further optimizes outcomes. This includes avoiding fine details smaller than 100-200 pixels, as they may become blurry during transfer. Also, ensure your design has a minimum transparent border of 5mm to prevent ink bleed. Using DTF transfer sheets specifically designed for your printer guarantees consistent results, ensuring that every print comes out vibrant and professional.

In conclusion, preparing artwork files for DTF Heat Transfers involves a meticulous process that begins with understanding the unique requirements of this technology. By optimizing your design for transfer during pre-preparation and adhering to specific file format, resolution, and printing guidelines outlined in our final touches section, you’ll ensure high-quality results. Mastering these steps will not only enhance the visual appeal of your heat transfers but also contribute to their durability and effectiveness on various materials.